| Static chamber dryers with loading

of materials on fixed or movable racks, or in manufactured packages of wer

bricks. Models RSD and PSD.

Semi-continuous type dryers with

loading of material on racks or on platforms, both movable. Model SMD.

|

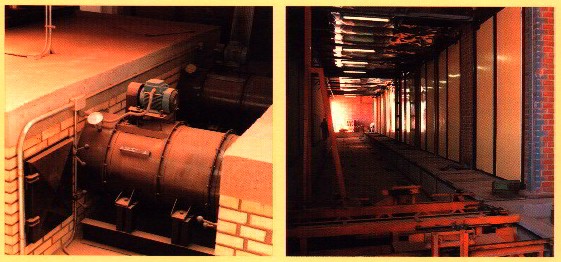

Continuous tunnel-type dryers with

loading of wet pieces on tunnel kiln wagons. Model CTD.

|

Rapid or accelerated type dryers

for drying cycles between 2 and 6 hours. Model PRD.

| |

Control od drying cycles is carried out by programmed regulation of humidity and temperature curves throughout the entire process.

Our systems of air recirculation inside the dryers a include solutions with periodic-movement mobile fans, or with static fan systems with alternation or inversion of recirculation way.

DRIERS

DRIERS